Assay results from four step-out drill holes west of the deposit contain high manganese grades with up to 45.80% Mn in individual samples. Results include1 :

- 40.94% Mn (52.86% MnO) over 7.92 meters within 19.43% Mn over 39.93m

- 38.94% Mn (50.28% MnO) over 3.23 meters within 19.12% Mn over 19.45m

- 45.80% Mn (59.14% MnO) over 1.53 meters within 15.60% Mn over 20.21m

Results from more western step-out drill holes at approximately 100m spacing are expected in coming weeks.

Toronto, Ontario, 21st September 2023: Electric Metals (USA) Limited (“EML” or the “Company”) (TSXV: EML) (OTCQB: EMUSF) is pleased to announce assay results from six cored drill holes at the high-grade Emily Manganese Project (“Emily Project”), Minnesota, USA.

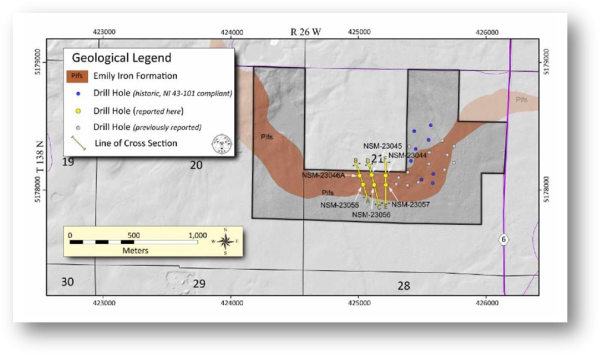

Previously reported results from the first fifteen diamond drill holes of the current program (refer announcements dated 27th June 2023, 13th July 2023 and 24th August 2023) described continuity of thick intervals of more than 30% manganese with a northerly dip and east-west strike direction. The results reported in this announcement are for an additional six drill holes located on 100-meter collar spacing (23044, 23045, 23046A, 23055, 23056 and 23057) which confirm that these high-grade, thick manganese intervals extend for at least another 300 meters further to the west (Table 1 and Figures 1-4).

The results to date from the Company’s 2023 drilling have shown that the high-grade manganese oxide mineralization (manganite) extends to at least 400 meters west of the 2020 NI 43-101 resource and has yet to be closed at depth or along trend (Figures 1 and 2, Table 1).

Step-out drilling at 100-meter drill collar spacing for approximately 400 meters has been completed to the west of holes 23046A and 23055 and assays from these seven holes are expected in coming weeks.

Representative high-grade drill core (Figure 5) is dominated by the dark grey to black manganese oxide mineral manganite (MnO(OH)). Analyses of core samples from drill hole 23057 from between 282 feet (85.95 meters) and 296.6 feet (90.40 meters) are listed in Table 2 and are typical for the high-grade portions of the deposit. The manganese content from samples taken from the core trays in Figure 5 ranges between 25.7%-42.3% Mn with a wider spread of iron assays (between 11.77%-29.17% Fe). The rock contains lesser contents of aluminium (2.69%- 5.36% Al2O3) and silica (1.80%-5.62% SiO2), minor amounts (less than 1%) of barium, calcium, potassium, sodium magnesium and trace phosphorus, strontium and titanium. There is no arsenic, chlorine, chrome, copper, nickel, lead, sulphur, vanadium or zinc in this selected core, and this is typical for the deposit.

Figure 1. Location of drill holes 23044, 23057, 23056, 23045, 23055 and 23046A showing the project area, manganese host rock (Emily Iron Formation) and the location of cross sections in Figures 2, 3 and 4.

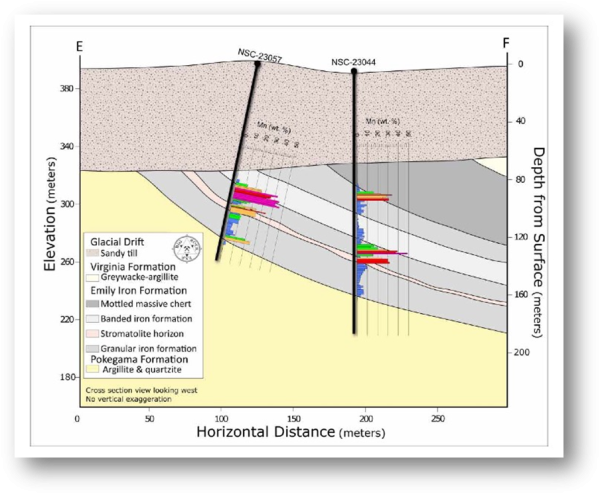

Figure 2. Cross section E-F (refer Figure 1) showing drill hole traces of 23057 and 23044, with manganese contents in assayed intervals and geology.

Figure 3. Cross section C-D (refer Figure 1) showing drill hole traces of 23056 and 23045, with manganese contents in assayed intervals and geology.

Figure 4. Cross section A-B (refer Figure 1) showing drill hole traces of 23055 and 23046A, with manganese contents in assayed intervals and geology.

Table 1. Average assay data for drill holes 23044, 23045, 23046A, 23055, 23056 and 23057 at the Emily Manganese Project 2.

Drill Hole Number |

From |

To |

Intercept Length |

From |

To |

Intercept Length |

Average Mn |

Average MnO |

Average Fe |

|---|---|---|---|---|---|---|---|---|---|

|

meters |

meters |

meters |

feet |

feet |

feet |

% |

% |

% |

|

|

23044 |

83.52 |

97.81 |

14.29 |

274 |

320.9 |

46.9 |

14.13 |

18.24 |

30.52 |

|

incl |

85.56 |

89.61 |

4.05 |

280.7 |

294 |

13.3 |

29.22 |

37.73 |

30.42 |

|

108.94 |

116.22 |

7.28 |

357.4 |

381.3 |

23.9 |

5.65 |

7.30 |

28.19 |

|

|

119.69 |

139.14 |

19.45 |

392.7 |

456.5 |

63.8 |

19.12 |

24.69 |

19.54 |

|

|

incl |

123.14 |

126.37 |

3.23 |

404 |

414.6 |

10.6 |

38.94 |

50.28 |

11.26 |

|

incl |

129.54 |

132.74 |

3.20 |

425 |

435.5 |

10.5 |

30.61 |

39.52 |

25.7 |

|

148.04 |

153.62 |

5.58 |

485.7 |

504 |

18.3 |

5.53 |

7.14 |

26.54 |

|

|

23045 |

66.14 |

73.37 |

7.23 |

217.0 |

240.7 |

23.7 |

23.14 |

29.88 |

35.00 |

|

79.64 |

82.91 |

3.27 |

261.3 |

272.0 |

10.7 |

7.36 |

9.50 |

26.15 |

|

|

87.42 |

98.69 |

11.27 |

286.8 |

323.8 |

37.0 |

4.84 |

6.25 |

30.60 |

|

|

105.16 |

131.37 |

26.21 |

345.0 |

431.0 |

86.0 |

15.48 |

19.99 |

19.50 |

|

|

incl |

106.38 |

121.31 |

14.93 |

349.0 |

398.0 |

49.0 |

21.79 |

28.14 |

21.03 |

|

incl |

109.42 |

114 |

4.58 |

359.0 |

374.0 |

15.0 |

28.01 |

36.17 |

16.89 |

|

incl |

116.59 |

121.31 |

4.72 |

382.5 |

398.0 |

15.5 |

28.56 |

36.88 |

22.90 |

|

139.42 |

145.63 |

6.21 |

457.4 |

477.8 |

20.4 |

6.89 |

8.90 |

17.97 |

|

|

23046A |

71.99 |

85.34 |

13.35 |

236.2 |

280.0 |

43.8 |

13.82 |

17.84 |

31.47 |

|

101.13 |

105.37 |

4.24 |

331.8 |

345.7 |

13.9 |

7.82 |

10.10 |

28.27 |

|

|

112.38 |

132.59 |

20.21 |

368.7 |

435.0 |

66.3 |

15.60 |

20.14 |

19.20 |

|

|

incl |

114.60 |

119.79 |

5.19 |

376.0 |

393.0 |

17.0 |

27.15 |

35.06 |

14.98 |

|

incl |

118.26 |

119.79 |

1.53 |

388.0 |

393.0 |

5.0 |

45.80 |

59.14 |

9.52 |

|

incl |

122.53 |

125.46 |

2.93 |

402.0 |

411.6 |

9.6 |

25.88 |

33.42 |

24.57 |

|

139.81 |

142.28 |

2.47 |

458.7 |

466.8 |

8.1 |

5.96 |

7.70 |

22.34 |

|

|

23055 |

69.8 |

72.83 |

3.01 |

229 |

238.9 |

9.9 |

5.63 |

7.27 |

14.47 |

|

80.92 |

89.55 |

8.63 |

265.5 |

293.8 |

28.3 |

15.32 |

19.78 |

22.36 |

|

|

incl |

84.43 |

88.76 |

4.33 |

277 |

291.2 |

14.2 |

17.63 |

22.76 |

22.4 |

|

23056 |

80.16 |

91.14 |

10.97 |

263 |

299 |

36 |

5.97 |

7.71 |

18.13 |

|

23057 |

84.43 |

124.36 |

39.93 |

277 |

408 |

131 |

19.43 |

25.09 |

20.42 |

|

incl |

87.9 |

95.83 |

7.92 |

288.4 |

314.4 |

26 |

40.94 |

52.86 |

14.15 |

|

incl |

94.95 |

95.83 |

0.88 |

311.5 |

314.4 |

2.9 |

45.80 |

59.14 |

11.39 |

Table 2. Assay data of selected drill core from 23057. The drill core trays with drilled intervals between 282 feet (85.95 meters) and 296.6 feet (90.40 meters) photographed prior to sampling are shown in Figure 4.

| Hole number |

From |

To |

Length |

Sample Number |

Mn |

Al2O3 |

As |

Ba |

CaO |

Cl |

Co |

Cr2O3 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

feet |

feet |

feet |

% |

% |

% |

% |

% |

% |

% |

% |

||

|

23057 |

282.0 |

285.0 |

3.0 |

H798727 |

25.70 |

3.29 |

0.02 |

0.74 |

0.16 |

0.00 |

0.01 |

0.00 |

|

23057 |

285.0 |

288.4 |

3.4 |

H798728 |

26.30 |

5.36 |

0.02 |

0.83 |

0.83 |

0.00 |

0.02 |

0.00 |

|

23057 |

288.4 |

292.0 |

3.6 |

H798729 |

42.30 |

2.69 |

0.02 |

0.94 |

0.94 |

0.00 |

0.02 |

0.00 |

|

23057 |

292.0 |

296.6 |

4.6 |

H798731 |

36.00 |

4.25 |

0.02 |

1.02 |

0.24 |

0.00 |

0.04 |

0.00 |

|

Hole number |

From |

To |

Length |

Sample Number |

Cu |

Fe |

K2O |

MgO |

Na2O |

Ni |

P |

Pb |

|

feet |

feet |

feet |

% |

% |

% |

% |

% |

% |

% |

% |

||

|

23057 |

282.0 |

285.0 |

3.0 |

H798727 |

0.01 |

29.17 |

0.73 |

0.23 |

0.12 |

0.01 |

0.14 |

0.01 |

|

23057 |

285.0 |

288.4 |

3.4 |

H798728 |

0.01 |

24.69 |

0.56 |

0.30 |

0.10 |

0.01 |

0.31 |

0.01 |

|

23057 |

288.4 |

292.0 |

3.6 |

H798729 |

0.02 |

11.77 |

2.05 |

0.31 |

0.30 |

0.01 |

0.09 |

0.01 |

|

23057 |

292.0 |

296.6 |

4.6 |

H798731 |

0.04 |

17.78 |

1.82 |

0.31 |

0.22 |

0.02 |

0.11 |

0.01 |

|

Hole number |

From |

To |

Length |

Sample Number |

Sulfur |

SiO2 |

Sn |

Sr |

TiO2 |

V |

Zn |

LOI |

|

feet |

feet |

feet |

% |

% |

% |

% |

% |

% |

% |

% |

||

|

23057 |

282.0 |

285.0 |

3.0 |

H798727 |

0.00 |

3.50 |

0.00 |

0.09 |

0.29 |

0.02 |

0.01 |

12.1 |

|

23057 |

285.0 |

288.4 |

3.4 |

H798728 |

0.00 |

5.62 |

0.00 |

0.08 |

0.26 |

0.01 |

0.01 |

13.1 |

|

23057 |

288.4 |

292.0 |

3.6 |

H798729 |

0.00 |

1.95 |

0.00 |

0.26 |

0.17 |

0.00 |

0.02 |

12.8 |

|

23057 |

292.0 |

296.6 |

4.6 |

H798731 |

0.00 |

1.80 |

0.00 |

0.23 |

0.14 |

0.01 |

0.02 |

12.9 |

Figure 5. Manganese mineralization within granular iron formation in drill core from hole 23057. Assay data for samples from between 282 feet (85.95 meters) and 296.6 feet (90.40 meters) are listed in Table 2.

Gary Lewis, Group CEO of Electric Metals commented on the latest results from Emily: “The thickness and grades of manganese continues to extend in new ground to the west of the current resource area. Drilling along the shallow southern edge of the north-dipping deposit has defined excellent continuity of high-grade manganese and this will assist future mine studies for the deposit. We are looking forward to reporting assays for the remaining seven holes when analyses are completed in coming weeks.”

“With logging and sampling of drill core now complete, and final samples at the lab for assaying, our technical team is now focused on advancing the metallurgical testwork and finalizing the updated NI 43-101 mineral resource estimate, which remains on track for delivery in Q4:2023. Key environmental baseline studies are also scheduled to commence in coming weeks.”

Qualified Person

The scientific and technical data contained in this news release was reviewed and approved by Ian James Pringle PhD, who is a Qualified Person under National Instrument 43-101 Standards of Disclosure for Mineral Projects.

About Electric Metals (USA) Limited

Electric Metals (USA) Limited (TSXV: EML) (OTCQB: EMUSF) is a U.S.-based mineral development company with manganese and silver projects geared to supporting the transition to clean energy. The Company’s principal asset is the Emily Manganese Project in Minnesota, which has been the subject of considerable technical studies, including a National Instrument 43-101 Technical Report – Resource Estimate, with over US$26 million invested to date. The Company’s mission in Minnesota is to become a domestic U.S. producer of high-purity, high-value manganese metal and chemical products for supply to U.S. energy, technology and industrial markets. With manganese playing a critical and prominent role in lithium-ion battery formulations, and with no current domestic supply or active mines for manganese in North America, the development of the Emily Manganese Project represents a significant opportunity for America, the State of Minnesota and for the Company’s shareholders. In addition, the Company owns and operates the Corcoran Silver-Gold Project and the Belmont Silver Project in Nevada, with the former also having been the subject of a National Instrument 43-101 Technical Report – Resource Estimate.

Neither the TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in the policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release.

For further Information please contact:

Gary Lewis, Group CEO & Director: (647) 846 5299 - gl@electricmetals.com

Caution Regarding Forward-Looking Information

Certain statements contained in this news release constitute forward-looking information. These statements relate to future events or future performance. The use of any of the words "could", "intend", "expect", "believe", "will", "projected", "estimated" and similar expressions and statements relating to matters that are not historical facts are intended to identify forward-looking information and are based on EML's current belief or assumptions as to the outcome and timing of such future events. Actual future results may differ materially. In particular, this news release contains forward-looking information relating to, among other things, the development of the Company’s projects. Those assumptions and factors are based on information currently available to EML. Although such statements are based on reasonable assumptions of EML's management, there can be no assurance that any conclusions or forecasts will prove to be accurate.

While EML considers these statements to be reasonable based on information currently available, they may prove to be incorrect. Forward-looking information involves known and unknown risks, uncertainties and other factors which may cause the actual results, performance or achievements to be materially different from any future results, performance or achievements expressed or implied by the forward-looking information. Such factors include market risks and the demand for securities of the Company, risks inherent in the exploration and development of mineral deposits, including risks relating to changes in project parameters as plans continue to be redefined, risks relating to variations in grade or recovery rates, risks relating to changes in mineral prices and the worldwide demand for and supply of minerals, risks related to increased competition and current global financial conditions, access and supply risks, reliance on key personnel, operational risks, and regulatory risks, including risks relating to the acquisition of the necessary licenses and permits, financing, capitalization and liquidity risks.

The forward-looking information contained in this news release is made as of the date hereof, and EML is not obligated, and does not undertake, to update or revise any forward-looking information, whether as a result of new information, future events or otherwise, except as required by applicable securities laws. Because of the risks, uncertainties and assumptions contained herein, investors should not place undue reliance on forward-looking information. The foregoing statements expressly qualify any forward-looking information contained herein.

1 Drilled intervals shown are close to true thickness.

2 Assaying undertaken by ALS (Reno, NV) included a 23-element suite (ME-XRF21). High manganese samples (>25% Mn) were re-assayed using ME ICP81.